Behind the seams: Brooks Biomechanics lab

Did you know our footwear is designed and tested in-house? The state-of-the-art Brooks Biomechanics Lab delivers cutting-edge innovation straight to your feet.

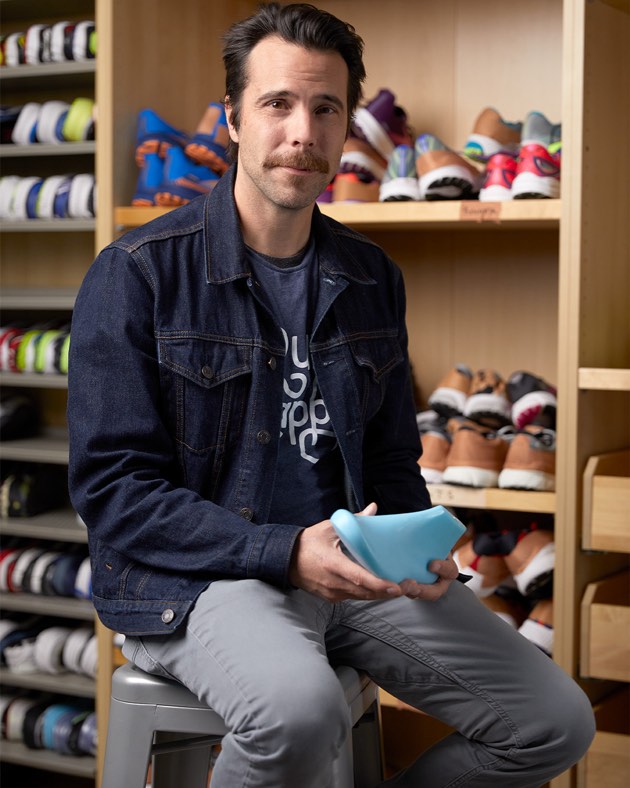

The lab is made up of world-class scientists and researchers committed to studying how the body moves while running and applying that knowledge to gear design. “Over 20 years, I’ve learned how footwear can influence human movement to help keep runners safe and healthy to achieve whatever their running goals may be,” says Senior Manager of Footwear Engineering Zach Boteilho.

Go behind the seams with the Brooks Biomechanics Lab to learn about the innovation that makes Brooks footwear special.

Senior manager of Footwear Engineering Zach Boteilho and senior manager of Product Assessment Jen Sumner are key members of our in-house Biomechanics team.

It all starts with Run Signature

We mean it when we say every runner is unique. Thanks to years of study, our research team found that everyone’s body moves in what is called a habitual motion path. Your habitual motion path is the path of least resistance for the unique alignment of your joints.

Habitual motion path

Your habitual motion path is at the core of our Run Signature philosophy, which aims to ensure optimal product performance, comfort, and reduced injury risk.

“Run signature is based on how your body is built, without the run taken into account yet,” explains Jen Sumner, senior manager, Product Assessment. “When we create a certain product experience, we lean into what happens when there’s an extra load on your body that is different from what you’re doing all day long.”

Put another way, while your joints are usually pretty good at doing their thing, running adds an extra load to your joints and can cause them to deviate from their natural motion path. This can increase the risk of injury and lead to discomfort while running.

After all, chances are good that if you run regularly — or irregularly — you’ve experienced hip, knee, or ankle pain.

To help runners reduce or avoid that pain, our scientists developed the GuideRails® support system. What is unique about GuideRails support is that it doesn’t try to “fix” your run, instead it supports the special way your body moves on the run.

“Waking up and deciding to run or walk is sometimes the absolute biggest step someone can make for their personal health. I just want the products we work on to be a suitable option for them,” says Boteilho.

Waking up and deciding to run or walk is sometimes the absolute biggest step someone can make for their personal health. I just want the products we work on to be a suitable option for them.”

The tools of the trade

The scientists in our Biomechanics lab use state-of-the-art technology to design and test our footwear to make sure it meets our standards, and yours.

“We don’t take into account just the first 5 miles of the run, we look at what’s happening at 15 miles into a run and ask how we build a shoe that does what it needs to do at that point in somebody’s run,” explains Boteilho.

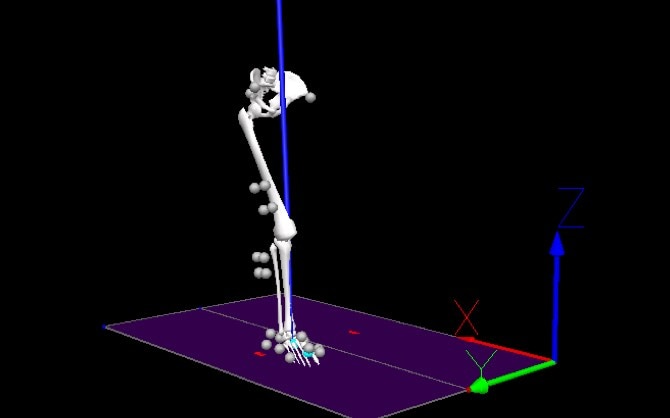

A key tool in the biomechanics toolbox is 3D motion capture, which models human movement using retroreflective markers placed across the body at bony landmarks . This allows scientists to see how the body moves naturally, and in different products.

A view of the 3D motion capture tool, which uses key markers on the body to measure movement and inform footwear design.

Along with 3D motion capture, an instrument treadmill is used to gather ground reaction force data, which gets paired with the movement data to create a full picture of how certain midsole foams, or technology like GuideRails can impact your run.

“Our biggest human movement exploration is comparing the difference between the two,” says senior research scientist Chris Ertel.

All these data points can add up to big innovations, but the most important data point is you — the runner.

Runner feedback is at the core of what we do. It’s this information that informs our design process and decision making. Biomechanics lab members like Sumner will recruit thousands of runners from across the country to participate in six-week footwear test “sessions”. Testers will log miles in prototype product and fill out 100-question surveys cataloguing their experience.

This information is used to inform shoe design down to the smallest detail. “Almost every single thing on the shoe is going to have an influence on fit, feel, ride, and ultimately, experience. The simplest lines you carve into the side of the shoe can completely change how your ankle is going to land, or how it’s going to accept weight, and ultimately, how it feels,” explains Sumner.

The specialists in our biomechanics lab use cutting edge technology to create the best footwear for all runners.

The big picture

The Biomechanics lab, and the scientists who drive its innovation, is crucial to product development at Brooks. The scientists and designers in the Biomechanics lab work closely with the BlueLine lab, the team who produced the Aurora BL and explores creative concepts in product design.

“One advantage of ours is that we are just one big collaborative team,” says Ertel. “So as we all work on different projects, we share those learnings regularly so that we can all use that information to build better product.”

As the team at the Biomechanics lab looks to the future, they are all motivated by the chance to create a uniquely new running experience . It can take up to three years to develop a new shoe, and every individual in the lab plays a role in its development.

“One of the best parts of my job is working with the Biomechanics and Product Testing teams who bring science and data to our collaborative groups...I enjoy helping them understand how to optimize their designs by combining Brooks core technologies with data to build something new that will help runners,” says Boteilho.

Looking forward

Brooks prides itself on leading the run industry in research and innovation, none of which would be possible without the dedicated individuals in our Biomechanics lab. Their work stems from passionate research and undergoes rigorous critique before landing in a shoebox that, hopefully, you’ll open someday.

“It’s one thing to have the products we work on be a part of [a] person’s journey, but it really boils down to the story of someone improving their life through exercise. That inspiration makes this one of the best jobs,” Boteilho explains.

No matter where you are in your running — or walking! — journey, the team in our Biomechanics lab is dedicated to perfecting your experience .