Our approach

At Brooks, we know that a responsible global supply chain starts with the decisions we make. That is why we establish long-term relationships with factories that share our objectives to trace our supply chain, respect human rights, and strengthen environmental management.

Our responsible sourcing efforts are guided by three objectives:

| OBJECTIVE 1 Trace our supply chain. | OBJECTIVE 2 Respect human rights. | OBJECTIVE 3 Strengthen environmental management. |

Collaborate with factories to expand visibility into our manufacturing supply chain.

Our goal:

- Conduct traceability for new footwear and other priority1 styles.

Visibility into the factories that manufacture Brooks products, materials, and raw materials, none of which we own or operate, is critical to enforcing the responsible sourcing standards outlined in our Supplier Code of Conduct are upheld. The expansive and complex nature of footwear and apparel supply chains makes this visibility difficult. Therefore, in 2022 we invested in a software solution called TrusTrace to help us continuously discover and trace factories throughout the Brooks manufacturing supply chain.

An example of a raw material’s journey through the Brooks supply chain

TIER 4 FACTORY OR FARM:

Collects raw materials (think plastic bottles)

TIER 3 FACTORY:

Processes raw materials, like turning plastic pellets into yarn

TIER 2 FACTORY:

Manufactures materials, like weaving\yarn into fabric

TIER 1 FACTORY:

Assembles components to make the final product

FINAL SHOE

Our approach to product traceability

In alignment with our seasonal business, twice a year we request that our Tier 1 and Tier 2 suppliers identify Tier 3 and Tier 4 suppliers they use for the manufacture of some Brooks product. Information about their facilities and production is collected to help us understand their role in our manufacturing supply chain. Tier 1 and Tier 2 suppliers are then requested to use purchase orders to substantiate their disclosed supply chains and submit documents that track the origin, movement, and handlers of materials and styles.

With this broad view of our manufacturing supply chain, we then identify the suppliers and factories that are involved in producing a particular style. Our approach is to trace new and priority styles entering the market in a given season. For each style, we prioritize tracing key materials and components that make up the majority of that style’s weight. We ask suppliers to trace each material and component to the raw material level, giving us deep visibility into the manufacturing supply chain of the product.

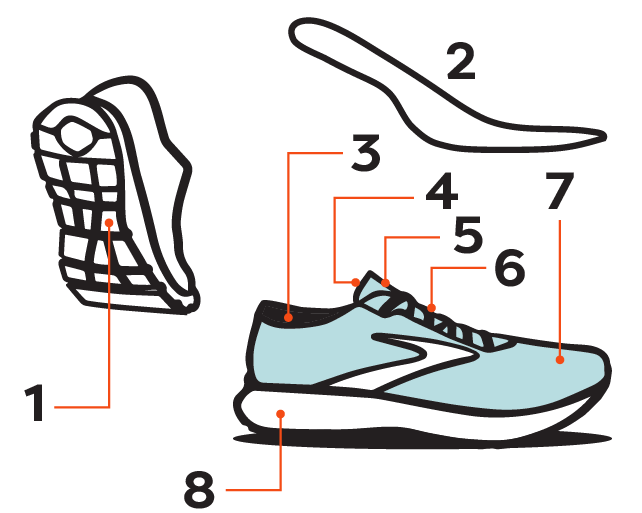

Components traced to the raw material supplier

Shoe: 1: Outsole; 2: Sockliner top cloth; 3: Collar lining; 4: Tongue lining; 5: Tongue textile; 6: Lace; 7: Vamp textile; 8: Midsole

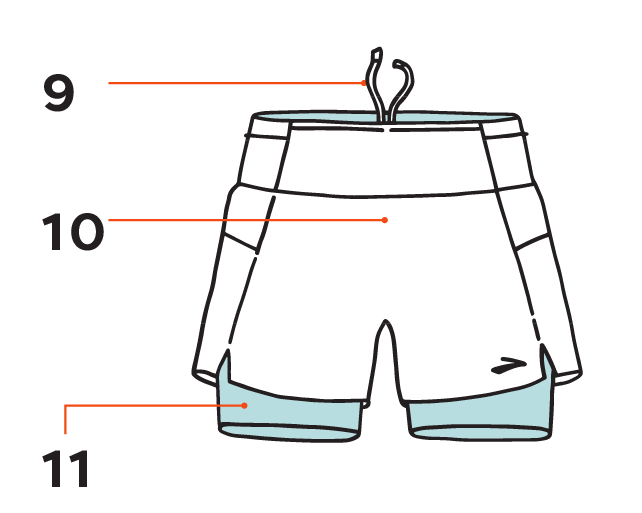

Shorts: 9: Trim; 10: Shell fabric; 11: Lining fabric

Risk identification and mitigation

This deep supply chain visibility is also used to help identify and mitigate responsible sourcing risks, increase due diligence for customs compliance, and identify business continuity risks. Our traceability program is designed to leverage intelligence tools to quarterly screen known suppliers, Tier 1 through Tier 4, to help ensure that all known suppliers are in compliance with U.S. and international trade regulations. For any identified risks, we collaborate closely with suppliers to assess the relevance and impact of the risk and take actionable steps to remediate issues. Any significant risks that cannot be remediated will result in termination of business.

Our traceability program is rooted in transparency, trust, and collaboration, and through these values we will continue to bring responsible sourcing practices to the suppliers we know and those we have yet to discover. We believe it is important to be transparent about where our products are made. Learn more about factories in the Brooks manufacturing supply chain on our Supply Chain Transparency page.

Align with factories that share our values in respecting human rights, promoting fair and safe working conditions, and advancing employee well-being.

Our goal:

- 100% of in-scope factories1 annually complete a verified social compliance assessment

Policies and standards

We ground ourselves in the Universal Declaration of Human Rights and the International Labor Organization Declaration on Fundamental Principles and Rights of Work. We also align our policies and standards with international best practices, including the Ethical Trade Initiative base code and Business Social Compliance Initiative (BSCI).

The Brooks Supplier Code of Conduct (Code) is the foundation of our responsible sourcing program. Together with local laws and international labor laws, it sets the standards for all factories in our manufacturing supply chain.

The Code is organized around five principles:

TRANSPARENCY AND COLLABORATION

COMPLIANCE WITH LOCAL AND INTERNATIONAL LAWS AND REGULATIONS

A SAFE AND HEALTHY WORKING ENVIRONMENT

FAIR COMPENSATION

ENVIRONMENTAL MANAGEMENT

Key topics addressed by the Code include:

- Health and safety

- Child labor

- Forced labor

- Working hours

- Wages and benefits

- Harassment, abuse, and discipline

- Non-discrimination

- Freedom of association and collective bargaining

- Environmental management

- Chemical management

The Code is part of the purchase agreement and must be signed by all suppliers who manufacture Brooks product and materials to ensure a common vision, accountability, and transparency.

Compliance with our Code

As part of our new supplier onboarding process, Brooks requires all factories to sign the Brooks Supplier Code of Conduct, which certifies:

- They meet or exceed the requirements in the Code

- They will maintain current and detailed records to substantiate compliance with the Code

- They will be transparent with Brooks in all respects, providing documents with accurate working hours and payroll records when requested

- Any Brooks merchandise will be produced in compliance with the wage and working hours laws of the country of manufacture and without the use of child, prison, or forced labor

- They understand that failure to comply with the Code may result in termination of business with Brooks

Additionally, Brooks requires all prospective factories to complete a verified social compliance assessment to evaluate social and labor practices and verify compliance to our Code.

In 2021, as a Cascale member and a signatory of the Social Labor Convergence Program (SLCP), we aligned with the apparel and footwear industry by adopting the SLCP Converged Assessment Framework (CAF) and replacing our traditional third-party audit approach. This industry-standardized social compliance assessment measures social labor practices in factories across nine key areas:

- Recruitment and hiring

- Working hours

- Wages and benefits

- Worker treatment

- Worker involvement

- Health and safety

- Termination

- Management systems

- Empowering people and communities

The assessment can be shared with brands via Worldly's Higg Index. The SLCP has also collaborated with Better Work, an International Labor Organization program that assesses compliance with international labor laws to improve working conditions. This collaboration means that Better Work will use the SLCP CAF assessment during their social compliance assessments to reduce audit fatigue and promote data sharing in the industry. As a Cascale member, we encourage our factories to use Worldly to complete their social compliance assessment through the Higg Facility Social Labor Module (Higg FSLM); however, we also accept verified social compliance reports through Better Work. This ensures we are doing our part to help reduce duplicative auditing and costs for our suppliers.

The SLCP CAF evaluation begins with a self-assessment completed by the factory that is subsequently verified by an SLCP-approved verifier to confirm that assessment questions were understood and answered correctly and the data is reliable. During verification, approved verifiers review the factory’s responses and conduct semi-announced onsite verification, which includes an opening and closing meeting, document review, factory employee interviews, and a facility walk-through. With industry adoption of this tool, duplicative auditing is eliminated, and brands can collaborate with their shared factories to use one data set to drive social and labor improvements in their supply chains.

Once factories are successfully onboarded, we annually evaluate 100% of our Tier 1 final assembly factories to help ensure their continued compliance with our Code and local law through a verified social compliance assessment. We use a risk-based approach to determine our engagement level with Tier 2 material factories, prioritizing our annual engagement with factories that account for approximately 80% of our materials volume by dollar spend.

We recognize that forced labor concerns of foreign migrant workers are among the most serious challenges facing the apparel and footwear industry. As a founding signatory of the Commitment to Responsible Recruitment, we commit to work with our factories and expect that no worker pays for their job, workers receive a timely refund of fees and costs paid to obtain or maintain their job, workers retain control of their travel documents, and all workers are informed of the basic terms of their employment before leaving home.

Beyond annual assessments

While we believe our use of annual verified social compliance assessments are critical to the success of our Responsible Sourcing efforts, we recognize that these assessments only capture the social and labor practices of a factory at a specific point in time. Therefore, we take the following three additional steps to ensure continuous compliance with local and international labor laws and our supplier Code of conduct, and ultimately to protect the human rights of factory employees.

1. Corrective Action Plan

Following completion of a verified social compliance assessment, we work closely with factories on a Corrective Action Plan (CAP) to remediate any identified issues that do not meet our standards.

In the spirit of continuous improvement, we rate factories twice throughout the CAP process. The assessment is initially rated following verification and then re-rated after the factory has been given two opportunities to show improvements. The final rating includes only those issues that have not been fully remediated. We believe it is critical to provide our factories with opportunities to improve within the same year to foster transparent relationships, motivate factories to remediate identified issues, and give factories an opportunity to explain any potential misunderstandings.

There are three kinds of ratings a factory can receive: Compliant, Needs Improvement, and Demands Immediate Action. If a factory receives a Compliant rating, no issues were found in their latest verified social compliance assessment. If a factory receives a Needs Improvement rating, one or more non-critical issues were found in their latest verified social compliance assessment. If a factory receives a Demands Immediate Action rating, at least one critical issue was found during their latest verified social compliance assessment. We identify a critical issue as high-risk non-compliance to our Code and/or local and national laws and regulations, and which compromises the basic human rights of a factory employee.

If a critical issue is found and a factory receives a Demands Immediate Action rating, Brooks will immediately set up a meeting with the factory to discuss the issue, assess the root cause, and work with the factory to implement a solution that quickly remediates the issue and prevents it from reoccurring. Factories who refuse or fail to remediate any critical issues risk termination of business with Brooks.

2. Factory employee survey

To complement our annual assessment and CAP and to further enhance our understanding of employee well-being, we annually implement LRQA’s Worker Sentiment Survey with all our footwear Tier 1 factories. This survey directly engages with the factory employees and provides them with a platform to share their perspectives. This survey is 100% anonymous and allows us to hear from significantly more employees than a traditional audit or SLCP CAF assessment. The survey scores factories on five topics based on direct employee responses: grievance mechanism, wages and working hours, workplace well-being, environment, health and safety, and productivity and stability.

Through analyzing the section scores, we gain insight into how employees feel about their compensation, management, and overall working environment. The Worker Sentiment Survey builds on the insights gained from a social compliance assessment and helps us develop a deeper understanding of employee satisfaction. Once we receive the survey results, we meet with each factory to discuss concerns raised by employees. Following the meeting, factory managers are required to develop an Improvement Plan in collaboration with their HR teams, trade unions, and employees to address the lowest scoring sections and ensure solutions are identified to create a better working environment from the perspectives of their employees. Brooks reviews the Improvement Plan and remains engaged with the factory to ensure the plan is implemented and progress is made.

3. Factory follow-up visits

Every October, we visit our strategic factories to review their latest performance and ensure alignment on expectations. These visits are intentionally planned for October, as factories have at that time already completed the verified social compliance assessment and worked on their CAP. This allows us to verify in person that issues have been resolved and processes have been put in place to ensure they don’t reappear. During this visit, we also engage with a group of randomly selected employees and trade union leaders to gain insight into working conditions from their perspectives. We take this time to ensure employees are aware of the Brooks Supplier Code of Conduct and understand how to utilize the grievance system to report issues if the factory is not compliant with the Code. This meeting is held privately with the Brooks Responsible Sourcing Team to ensure a safe space and encourage candid conversation.

The Brooks Responsible Sourcing Team also has representation in Vietnam, where the majority of our Tier 1 factories are located, and in close proximity to factories located in nearby countries. This allows us to plan additional visits, as needed, to support factories in meeting our expectations throughout the year.

Responsible purchasing practices

We are proud of the suppliers we work with who help bring Brooks product to life and believe they are critical to successfully achieving our goals. Our teams across sourcing, costing, innovation, corporate responsibility, quality, and product development visit our strategic factories at least once a year to ensure alignment across priorities, review progress towards our various objectives, and foster transparent and trusting relationships.

We also recognize that our internal purchasing practices could affect our suppliers’ abilities to comply with social and environmental laws, regulations, and our Code. To gain insight into how our suppliers view our internal practices, we collaborate with the Better Buying Institute (BBI), a non-profit organization that allows suppliers to anonymously rate the purchasing practices of their buyers. We annually deploy the Better Buying Partnership Index (BBPI) to all Tier 1 and high-volume Tier 2 factories1 to anonymously survey them about Brooks’ purchasing practices, such as accuracy of demand planning and forecasting. Upon completion of the survey, we review the results across various departments whose roles impact our purchasing practices such as costing, corporate responsibility, sourcing, and supply planning. After reviewing the feedback provided from our suppliers, we determine how to address low-scoring areas and drive improvements. Our work with BBI is our first step towards evaluating and improving our purchasing practices to ensure our business relationships with our suppliers are both responsible and mutually beneficial.

Work with factories that manufacture Brooks products and materials to implement environmental management systems that help promote more sustainable practices.

Our goal:

- 100% of in-scope factories1 annually complete a verified Higg FEM assessment

- 100% of input chemicals used at in-scope factories2 comply with the ZDHC MRSL (conformance Level 1) by 2030

- 100% of in-scope factories3 meet the minimum requirements of the ZDHC Wastewater guidelines by 2030

- Reduce organic solvent usage to 25 grams per pair by 2027

Environmental responsibility assessment

To achieve our objective of strengthening environmental management at the factories that manufacture Brooks product and materials, we assess each factory’s environmental performance through the industry-standardized tool, the Higg Facility Environmental Module (Higg FEM). We have used this tool with our Tier 1 final assembly factories since 2014, and since 2019, with our in-scope Tier 2 material suppliers. Following the completion of this self-assessment, all factories are required to verify the accuracy of their assessment via a Cascale-approved verifier.

Our expectation is that all factories achieve Higg FEM level 1. This level of performance indicates that the factory has a good understanding of its environmental impact and is tracking its sustainability performance. To improve performance, we review each verified assessment and identify specific actions the factory will need to take to achieve the level 1 performance requirement.

Learn more about additional strategies we’re implementing to reduce greenhouse gas emissions in our Tier 1 and Tier 2 factories.

Responsible chemicals program

Chemicals management is an important focus of our objective to achieve environmental compliance. The priority of our responsible chemicals program is to ensure factories that manufacture Brooks product and materials use only chemicals that are safe for people and the planet.

The Brooks Restricted Substances List (RSL) underpins the responsible chemicals program and defines those substances that we restrict or eliminate from our products. The Brooks RSL is updated on an ongoing basis to ensure it meets or exceeds global regulatory requirements, including California Proposition 65 and EU REACH. All materials in Brooks product must comply with our RSL. We communicate our restricted substances requirements to all our suppliers through our RSL and maintain this understanding through the Brooks Supplier Code of Conduct and RSL Compliance Agreement, which is signed by all suppliers with each updated version of our RSL.

Our responsible chemicals program goes beyond RSL compliance to take a holistic view of chemicals management. We require factories to manage chemicals entering the factory (input management), exiting the factory (output management), and in the factory (e.g., storage, handling, and inventory management). We’ve aligned with the wider apparel and footwear industry by adopting the Zero Discharge of Hazardous Chemicals (ZDHC) Manufacturing Restricted Substance List (MRSL) — a list of chemical substances banned from intentional use — and the ZDHC Wastewater Guidelines, which define standards and ensure the safety of wastewater discharge. We’re working towards 100% compliance with the ZDHC MRSL and zero discharge of hazardous chemicals by 2025. Our responsible chemicals program evaluates factory progress against this goal, and we proactively work with factories to identify areas where we can improve practices and ensure ZDHC standards are met.

Read more about our responsible chemicals program and RSL here.